Metalic Pumps

We are Authorized Dealer, Supplier of metalic Chemical Pumps and our setup is situated in Pune, Maharashtra, India.

metalic Pumps Pvt. Ltd was established in the year 1996, since then it has been

producing ANSI STD CHEMICAL PROCESS PUMPS, catering to a wide spectrum

of chemical industries. With the setup of new manufacturing facility in Gujarat,

metalic pumps now produces an entire range of ANSI series & ISO series Pumps

in Semi-open & Closed Impeller Constructions, having almost 80 Models to (Al

in various Materials of Construction. With the dream & vision of Mr. K.N. SHAH

(FOUNDER - ANTICO GROUP), the company was started by Mr. D.N. SHAH to

serve some of the finest process engineering requirements.

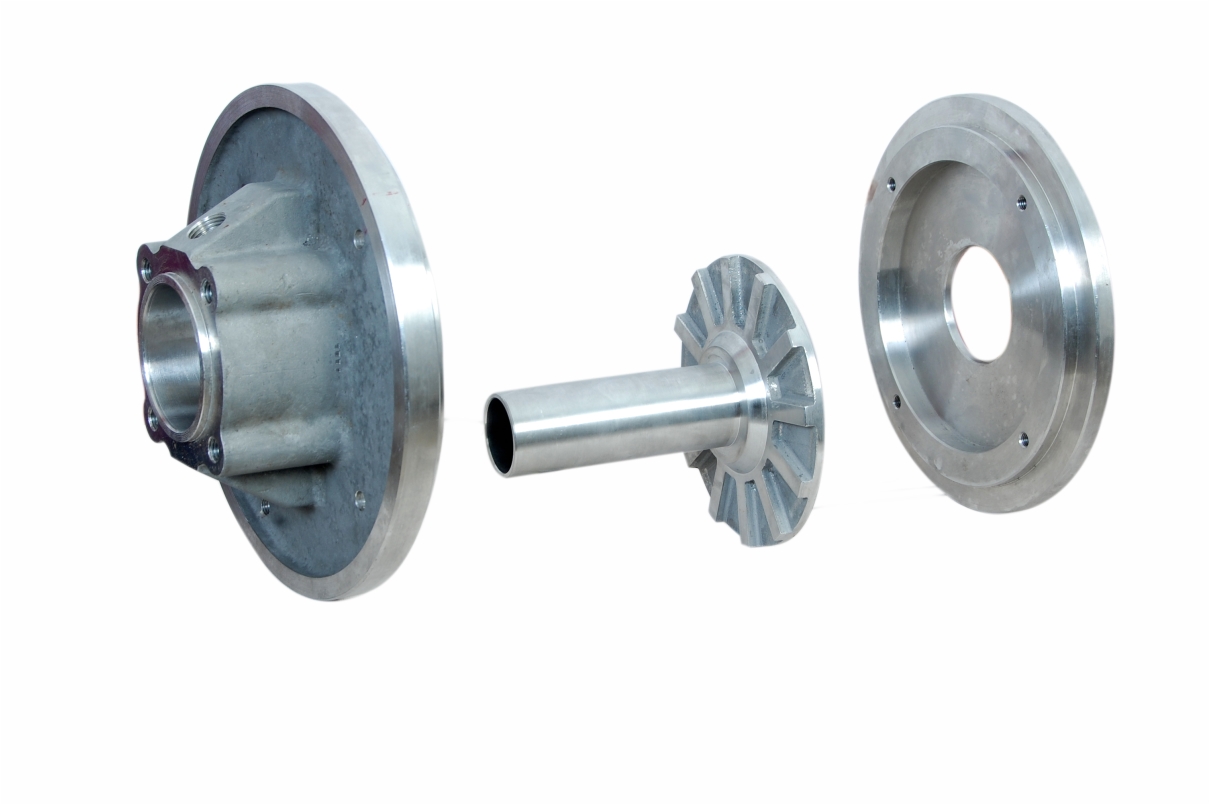

Semi - Open Type Impeller

- Max Capacity = 1000 m3hr

- Max Head = 150mts

- Temperature: -210°C to 2600 C

- Working Pressure: 2550 kPa

RANGE OF COVERAGE

Closed type Impeller

- Max Capacity = 1000 m3hr

- Max Head = 150mts

- Temperature: -210°C to 2600 C

- Working Pressure : 2550 kPa

RANGE OF COVERAGE

Vertical In - Line

Thermic Fluid Pumps Manufacturer in India »

Investa Pumps is one of the leading thermic fluid pumps manfacturer in India with over two decades of experience and expertise.

Filter Press Pump 1:

Properties & Advantages:

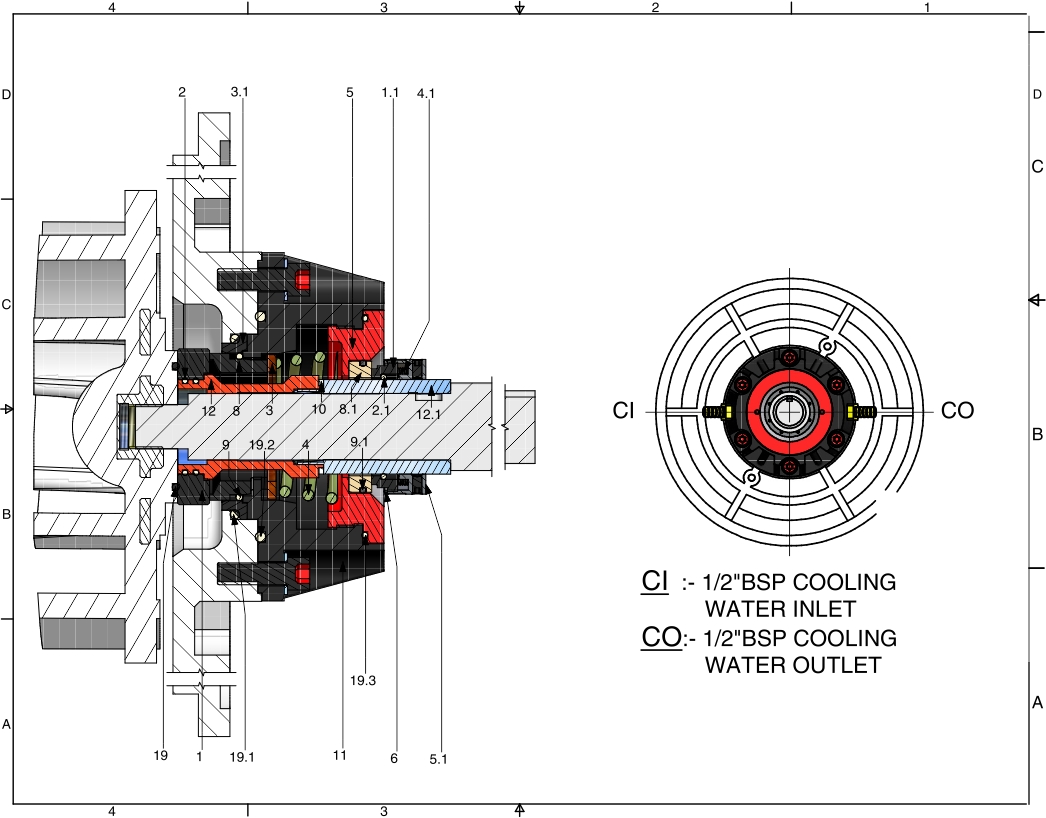

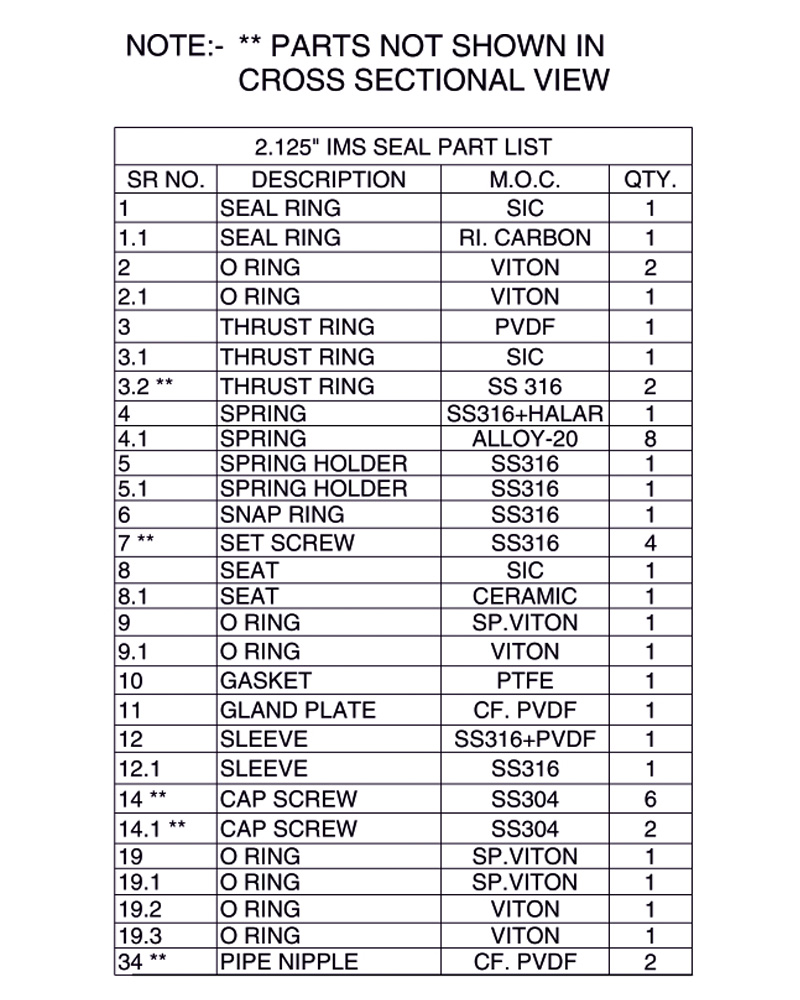

Completely Reversed balanced Internally Mounted Mechanical Seal Developed for High Slurry and Sludge Content Application.

Can work under very high back pressure.

Large Cross Sections and Thickness of Seal Face Parts in order to overcome the Difficulties in High Sludge Content Applications.

Can work very well continuously at higher RPM's as well.

Due to very High Pressure Requirements, at the Time of Effective cake Formation and Squeezing of Chamber Plates a very high amount of Back pressure is involved which is dealt very efficiently with this Mechanical Seal with it very hard Single Coil (Completely Stainless Steel with PVDF Coasted) Spring with all its other parts being product protected.

Can be an ideal replacement to a Positive Displacement Pumps

Properties & Advantages:

Completely Reversed balanced Internally Mounted Mechanical Seal Developed for High Slurry and Sludge Content Application.

Can work under very high back pressure.

Large Cross Sections and Thickness of Seal Face Parts in order to overcome the Difficulties in High Sludge Content Applications.

Can work very well continuously at higher RPM's as well.

Due to very High Pressure Requirements, at the Time of Effective cake Formation and Squeezing of Chamber Plates a very high amount of Back pressure is involved which is dealt very efficiently with this Mechanical Seal with it very hard Single Coil (Completely Stainless Steel with PVDF Coasted) Spring with all its other parts being product protected.

Can be an ideal replacement to a Positive Displacement Pumps

Filter Press Pump 2:

Double Mechanical Seal

Working Principle of Filter Presses »

Machines which are used to Filtrate Suspensions under high Pressurized Conditions in order to separate the Liquid and Solids.

It comprises of Set of Chamber Plates covered by Filter Cloth in order to Filter the Liquid and hold the Solid Particles under the Process of Pressurizing Sludge through a Feed Pump and Squeezing of Chamber Plates.

Dynamic Sealing Arrangement »

Applications: »

Acidic Slurries

Effluent Waste

Pigment Manufacturing

Mining

Urban or Industrial sludge Dewatering

Other Chemical and Pharmaceutical Applications

Investa Pumps offers its Self Priming Pumps in Vertical Construction for majorly solvents transfer handlings from the Tank Farms to the Charging vessels. This is majorly found in a lot of Active Pharma Ingredient Units.

Advantages of Self Priming Pumps »

A large vertical pump chamber acts as a Self-Priming Pot.

It has turbine type of fully open impeller for very efficient clear solvent handling.

Can be kept in a flameproof environment.

Can take a negative suction lift up to 3-5mts.

Investa offers them with a trolley mounted arrangements and so can be mobile in operations.

Can cover a horizontal distance of 40-45mts.

Comes with a drain valve arrangement.

A fully SS-316 body can be provided for various solvents (methanol, toluene, xylene) handling.

Since its construction being vertical in-line with suction and discharge in one line there is no use of axial or thrust bearings and can be used for a very efficient horizontal transfer of Bulk Drug operations. Investa offers these pumps out Investment Casting processes to have minimum casting rejections in heavy walled Casting chamber so as to deliver much quicker to the customers.

As the production of Bulk Drugs increases day by day and Project completion time for these companies worldwide reduces every day, the Investa Vertical Self Priming Pump helps in the fastest way whether it is Solvent Tanker Loading Unloading operations or transferring solvents from the Tank farms to the Charging Vessels.

Vertical Inline Pumps Manufacturer in India »

Investa Pumps manufacturers very specialized and sure shot solutions to Bulk Drug Transfer Applications for the Pharma Industry by providing their centripetal pumps or what we call as the Vertical In Line Pumps. These are all Self Prming by nature and excellent in handling various solvents from the Tank farms to the charging vessel. Major advantages for these pumps include:

Can lift from a negative suction upto 5mts.

Slow speed in operation so less wear and tear.

Can be provided with a trolley mounted arrangement for faster Batch Productions of these drugs.

With the ever increasing Bulg Drug capacities these Pumps are in the fore front in increasing the Production Capacities to the fullest and dispatching the end Product at the earliest. With the Suction and Discharge in One Line and with a Turbine Type Impeller it excels in handling Clear Solvents at its best. br The Vertical in Line Pumps also come out with Drain Valve arrangement to drain excess solvent back into drum so also can be useful in transferring inflammable sovents. These Pumps come with Vertical Flanged type Foot Mounted Motor arrangements.

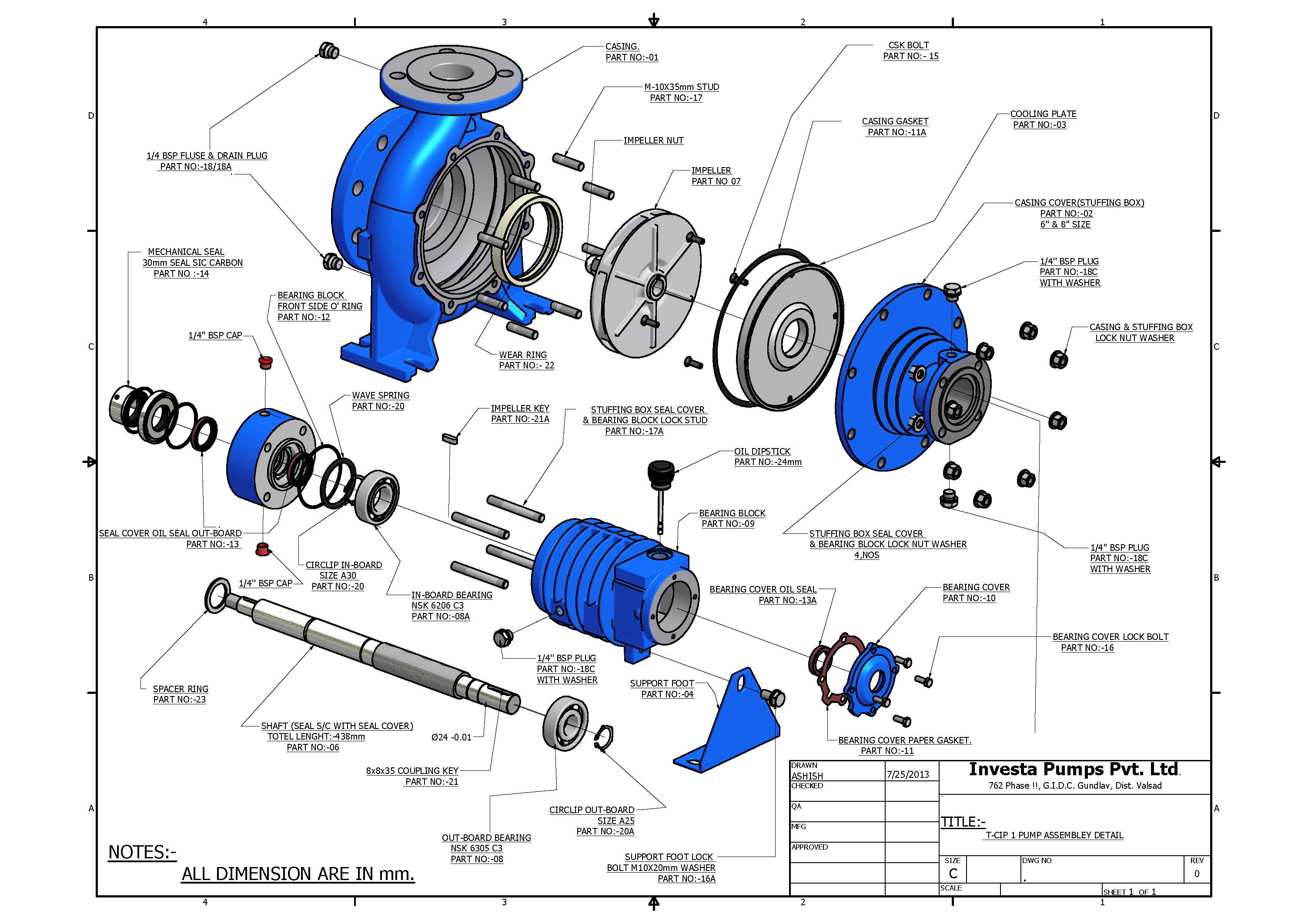

Investa Pumps are into manufacturing Pumps from Stainless Steel and Cast Iron or Cast Steel Castings for various duties in chemical plants. Their Cast Iron/Cast Steel Pumps are highly used in Water Pumping in Utility Sectors of Chemical plants.

Stainless Steel Pumps are generally consumed for various solvent handling applications or other Chemical handling applications pertaining to different industry. All these above Pumps have high wall thickness to take maximum pressure rating upto 20Bar. All the above CI/SS Parts are casts in different Induction Furnaces only to maintain the exact quality of Chemical Compositions. With superior casting finish for these pumps these pumps cater across the length and breadth of the nation.

For all these above Pumps all the Flange Standards are duly drilled as per Known Standard or can be as per Customer’s Standards as well. With having the best kind of Hydraulic Knowledge investa can produce highly efficient SS/CI pumps thus enabling the growth of any chemical plant.

Investa Pumps came into the foundation when Industrial growth was at its best in India. Investa Pumps are into manufacturing of Horizontal Chemical Process Pumps pertaining to the Chemical Sectors like Pharma and Bulk Drug, Chloro Alkali,Dyes and Intermediates, Agro Chem and Fertilizers,Speciality Chemicals, Pulp and Paper, Water Tretament, Distilleries, Palm Oil refining plants, steel mills and Mineral Recovery plants. With its manufacturing setup in Gujarat, Investa pumps comes in the forefront of giving Chemical Process Solutions.

More information »

Investa Pumps are manufacturing wide range of Industrial Pumps with over 80 Models of Pump sizes to offer in various materials of constructions. Having such wide spectrum in Pump range it cater to various as well as highly difficult Process Solutions as well. Investa Pump’s ultra modern facilities in its Foundry Setup and Pump manufacturing Setup leads them into the core definition of Industrial Pumps which targets into the hearts of most of the Chemical Processes Worldwide.

metalic Pumps now offers the new I-Mag Series of Pumps which are Magnetically Coupled Pumps for Highly Cryogenic & Toxic Liquids. These pumps are available up to 25 HP.

These pumps are available in ISO 2858 / 5199 Dimensions.

Available in NDFeBd / SmCo Rare earth Magnet.

The new power saver options offers pumps running at 1.5HP/2HP/3HP at 2900 rpm for handling clear solvents for the Active Pharma Ingradient (API) market.

| Sulphuric Acid | Brine | Nitric Acid |

| Sodium Hydroxide | Chlorosulphonic Acid | Maleic Acid |

| Hydrochloric Acid | Ethanol | Citric Acid |

| Acetic Acid | Phosphoric Acid | Sodium Chloride |

| Ammonium Chloride | Oleum | Vinyl Acetate |

| Butadiene | Vinyl Chloride | Formaldehyde |

| Benzene | Ethylene Glycol | Phenol |

| Toluene | Maleic Anhydride | Styrene |

| Ammonia | Acrylonitrile | Ethylene Oxide |

| Methanol | Urea | Xylene |

| Shower Water | Sodium Hypochlorite | Green liquor |

| White Water | Fresh Liquor | Dregs Washer |

| Chlorine Dioxide | Black Liquor | White Liquor |

| Sprage Water | Reclaim Water | Alcohol Transfer |

| Hot / Cold Wort | MASH | Yeast Brink |

| Chilled Water | Blow Black Beer | Sulphuric Acid |

| Beer | Spent Grain Liquor | Caustic |

| Copper Cyanide | Sodium Sulphate | Copper Sulphate |

| Sodium Cyanide | Ferric Chloride | Ammonium Sulphate |

| Chromic Acid | Ferrous Sulphate | Silver Cyanide |

| Condensate | Hot Oil | River Water |

| Deionized Water | Wine | Pond Water |

| Shower Water | Sugar Cane Juice | Cooling Tower Water |